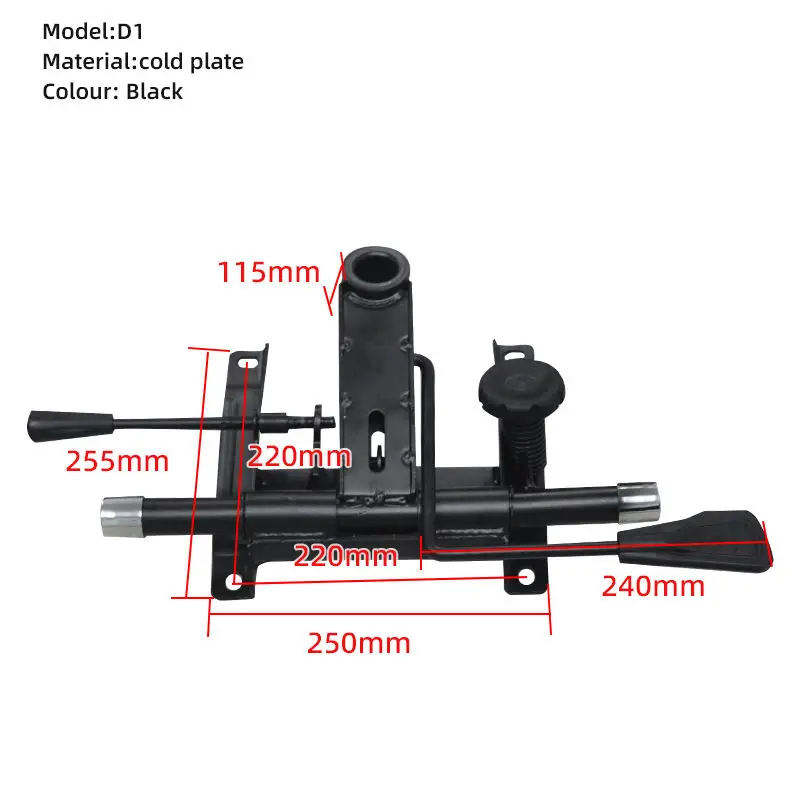

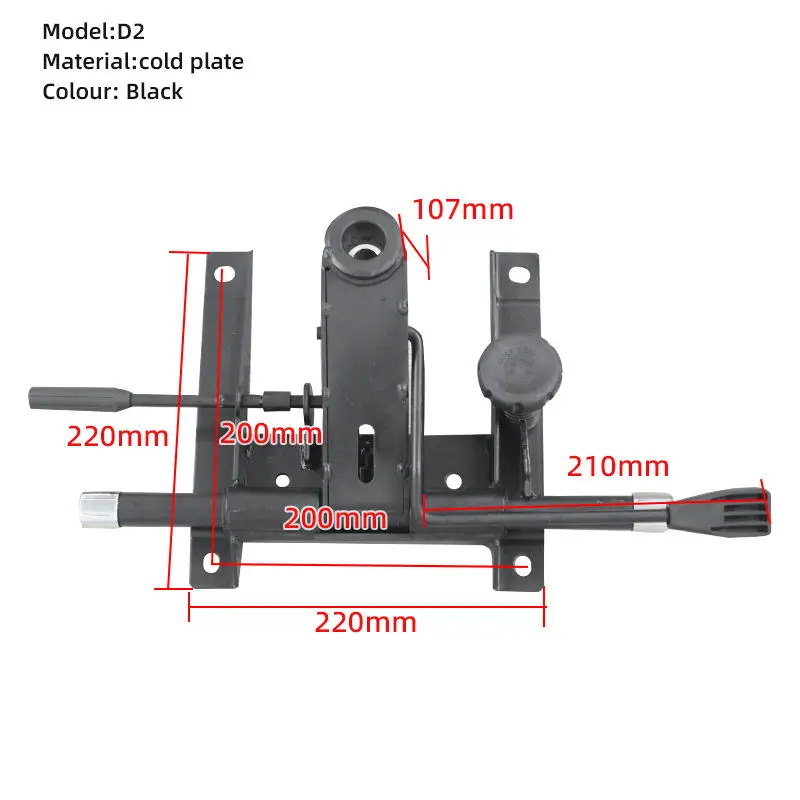

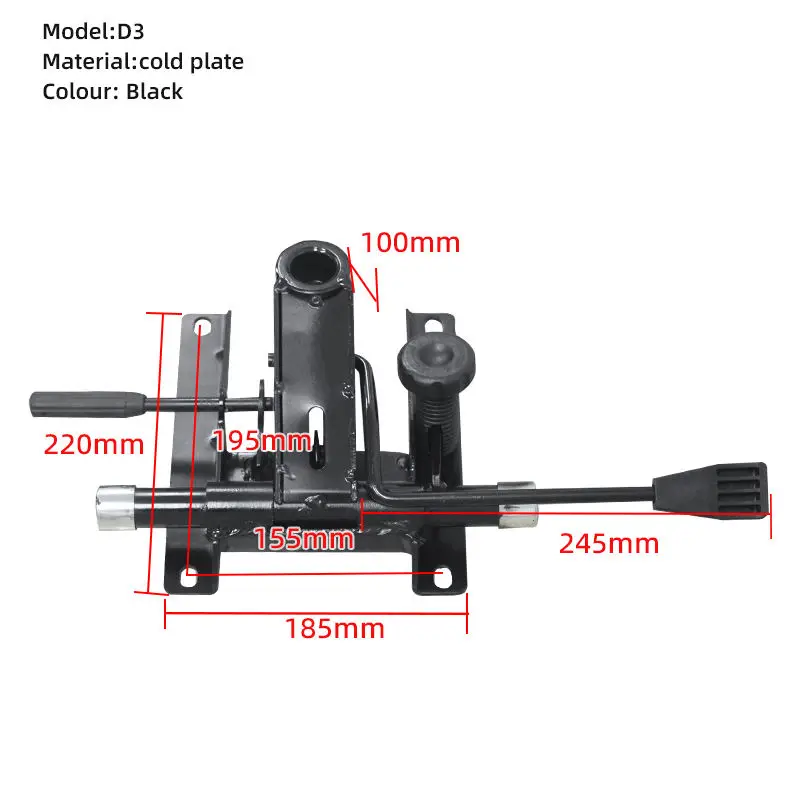

steel parts for chair butterfly chair mechanism

These steel parts are the structural backbone of the butterfly chair mechanism, ensuring its signature split-back flexibility, stable support, and long-term durability—critical for translating the mechanism’s ergonomic design into reliable user experience.

• Core Component Function: Specifically engineered for butterfly mechanisms, they include pivot shafts, connecting brackets, and tension adjustment plates. These parts enable the independent or synchronized tilt of the butterfly split backrests, letting users customize upper and lower back support (e.g., firm upper back for typing, slightly reclined lower back for rest) while maintaining structural alignment.

• Material & Durability: Made from high-strength cold-rolled steel (Q235/Q345 grade) or heat-treated alloy steel, with a thickness of 2.5-4mm. Surface treatments like electro-galvanization or powder coating provide corrosion resistance (passing 48-hour salt spray tests) and prevent rust, ensuring the parts withstand 60,000+ tilt cycles without deformation.

• Precision & Safety: Machined with CNC technology, the steel parts have a dimensional tolerance of ±0.1mm, ensuring smooth pivoting without jamming or creaking. Each part undergoes load-bearing tests (supporting 120-180kg) and features rounded edge designs to avoid scratching the mechanism’s other components or fabric, enhancing overall chair safety.